BFM® fitting is the global leader in flexible connector technology. The distinctive snap-in, flexible connector and spigot system eliminates the problems associated with traditional hose clamp connectors. This unique innovation is greatly improving powder handling processes worldwide, making them cleaner, safer and more efficient.

Over 10,000 sites worldwide solve process connection problems with BFM® fitting in industries as diverse as food, pharma, minerals and chemical.

As the authorised distributor for BFM® fitting in UK since 2007, we have a team dedicated to helping customers get the most from the BFM® range, including field-based application and technical assistance – all backed up by over £450,000 BFM® stock in our UK warehouse.

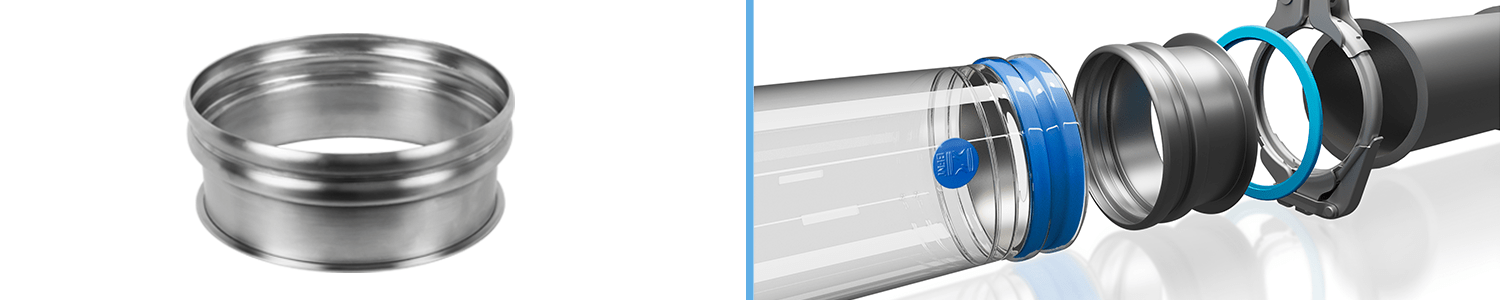

The system combines a unique snap-in, blue-banded flexible connector with specially formed steel spigots which are welded to inlets / outlets on a process line. Critically, the connectors snap internally within the spigot for effortless installation.

Advantages Of The BFM® fitting system:

• No Product Loss – 100% sealed, no mess, no leaks

• Explosion Resistant – seals tighter under pressure

• Better Health & Safety – protects staff & product

•Quick Changeovers – fastest in the market

•Streamline Inventory – easier stock control

•Durable Design – connectors last much longer

•Compliant – global food & explosion regulations

•Reduces Downtime – fewer clean-ups, fast changes

The standardised system can provide operational benefits throughout the factory. It is proven on hundreds of different powder handling applications, including sieves & sifters, silos & hoppers, mixers & blenders, conveyors & feeders, filling machines, metal detectors and rotary valves.

Specially designed to create a 100% dust tight, snap-in seal when combined with the BFM® connector. BFM® spigots are designed to be welded into place, fitting all standard metric or imperial pipework with use of a clever 52mm (2″) long tapered tail. Two material options are available, 304 stainless steel and 316 stainless steel to ensure full compliance.

Diameters include: 100mm, 125mm, and 150mm – 1650mm in 50mm increments.

Lipped spigots enable BFM® to be installed without welding as part of major modular piping systems. The 6mm rolled lip enables attachment to most major quick-release/pull-ring type clamps, including JACOB.

Diameters include: 100mm, 150mm, 200mm, 250mm, 300mm, 350mm & 400mm.

BFM® have created an extensive range of flexible connectors to meet the demands of different industries worldwide and to perform efficiently on a wide range of bulk handling and powder processing equipment.

BFM® connectors are available in a comprehensive range of standard nominal metric diameters and lengths, ensuring a consistent fit and better inventory control. Depending on the connector material specified, diameters range from 100mm-1650mm and lengths from 80mm-6000mm.

BFM® provide a number of options which can be specified within the connector range. Amongst options available, Tool Release (TR) connectors offer additional safety; Rings can be added to connectors for support / anti-collapse; and Tapered connectors can be used where outlet and inlet diameters differ or as a flexible hopper cone replacement. Contact the team for further detail.

In addition to the BFM® flexible connector range, providing a connection between pipework or machinery, the system is highly versatile and is used for a number of other applications.

BFM® Blanking Caps can be used to prevent contamination during clean down or change-over, or as sight-glasses / viewing ports.

BFM® Blanking Socks / Bins are ideal for sifter oversize collection bins, with the transparent Seeflex media allowing simple monitoring of fill level and reject consistency.

In addition to the BFM® flexible connector range, providing a connection between pipework or machinery, the system is highly versatile and is used for a number of other applications.

The Bulk Bag Loader uses BFM®’s patented spigot and snap-fit connector system to provide a fully sealed, inflatable bulk bag loading head that makes hygienic bag filling a breeze. The three-layered filling head features a stainless-steel core fully encased in Seeflex ether-based urethane.

Watch the video here –

The BFM® fitting consists of a blue banded flexible connector and depending on the type of connector usually two spigots – one on either end. The spigots are welded onto the machinery pipes and it is important to ensure that measurements are correct to get the perfect fit.

The BFM® Installation Gap (IG) Calculator will help you identify the correct Installation Gap for your BFM® fitting installation. You can download a copy of the calculator to use on a mobile device in the field or use it on-line, and you can also save calculations as pdf files to refer to later.

The installation gap is the space to leave between the BFM® spigots and always needs to be slightly shorter than the connector length (CL).

Note – The calculator is designed for installations with horizontal movement only – if vertical movement is also involved, please contact us for further guidance.

A wide range of BFM® fitting products have been independently tested and conform with the leading internationally recognised health and safety legislation.

For compliance information relating to specific BFM® products and materials, such as 3A, USDA, FDA, EC & ATEX, please contact us for further guidance and documentation.

For applications adjacent to moving machinery it is the clients’ responsibility to ensure compliance with regulatory requirements. Measures for consideration could include; Tool Release connectors, guarding, proximity switches, light sensors, internal grid/grille etc. Please contact us to discuss specific applications.

BFM® fitting is supported by a comprehensive and extensive suite of information. In addition to the below information, further BFM® fitting guidelines, compliance documentation and testing documents are available from our sales team or via the BFM® fitting website:

With such a comprehensive range of flexible connectors and associated connector solutions, BFM® can be used successfully across a wide range of applications throughout a production facility. The best way to navigate the full range is via a site visit from our dedicated team of Process Improvement Engineers.

Joe and the team offer application and installation advice, ensuring you get the optimal performance from your investment in BFM® fitting.

*Disclaimer - ProSpare does not warrant that any Goods will be suitable for any particular purpose of the Customer, whether or not that purpose has been made known by the Customer to the Company. The Customer assumes all risk and liability resulting from the use of the Goods and it is the Customer’s responsibility for compliance for any specific application.

Allicio Nutrition Ltd upgrades 25+ connection points to BFM® fitting - improving health and safety, reducing changeover time and eliminating product leaks.

A British pet food manufacturer reduces connector maintenance time from 2 hours to just 15 minutes and eliminates leakage points with BFM® fitting.

A UK-based Monolithic Refractory Manufacturer and Installer installed two BFM® Bulk Bag Loaders to improve the bulk bag loading stations during filling.

BFM® fitting makes daily connector changeover 75% faster for Richard Whittaker Ltd a UK-based specialist in the blending, packing and supplying industry saving around 250 hours per year.