As environmental responsibility becomes an ever-greater priority, food and beverage manufacturers face a crucial challenge: creating more sustainable manufacturing and supply chain operations. The Sustainable Food Factory Conference and Exhibition brings together people from the industry to learn, collaborate, network and share best practices in sustainable food and beverage operations.

Taking place on the 11th of June at Derby Arena, the conference promises a full schedule of industry leaders delivering informative presentations and thought-provoking panel debates to help navigate the sustainability challenges. The exhibition will feature the latest products, services and technologies to help you achieve and surpass sustainability goals.

BFM® fitting is the global leader in flexible connector technology. The distinctive snap-in, flexible connector and spigot system eliminates the problems associated with traditional hose clamp connectors. This unique innovation is greatly improving powder handling processes, making them cleaner, safer and more efficient.

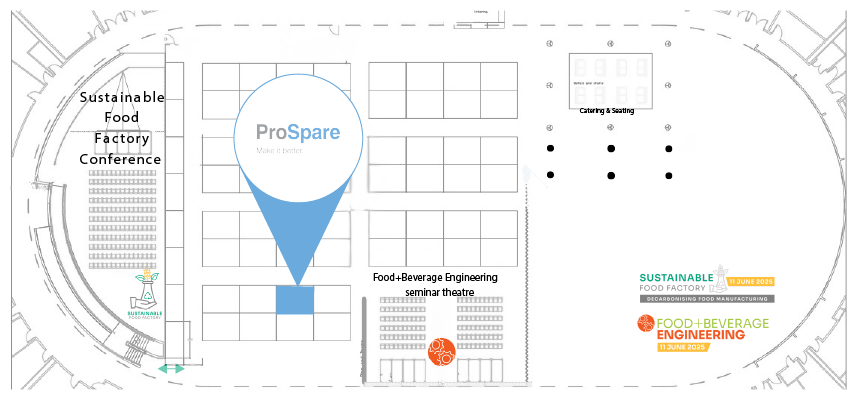

Members of the ProSpare team will be on stand C2 showcasing a selection of products from BFM® fitting. Our innovative display features a number of the standard options in the range, including 040e flexible connectors, compressible flexi-connectors, sifters overs collectors, blanking caps, and breather bags.

In addition to making processes cleaner, safer and more efficient, the team will showcase how BFM® is contributing to the sustainability of operations – both within their own processes and that of the clients using the world-renowned flexible connector system.

Our expert team will be on hand throughout the day. Stand staff will include:

Joe Cossey. General Manager – ProSpare

Tony Roe. Process Improvement Engineer – BFM® fitting

If you’d like to book an appointment with a member of our team in advance, please email sales@prospare.co.uk stating who you would like to see and your preferred time.

Flexible connectors are used extensively in virtually all processing industries. This wide-scale use means that identifying connectors with a long service life can provide valuable contributions to the sustainability of operations. BFM® fitting helps reduce the number of connectors disposed of through increased longevity.

We’re pleased to announce that Tony Roe has joined the BFM® department as a Process Improvement Engineer in the field. Tony will be available to help customers navigate our extensive range of BFM® fitting options for a wide range of applications in various sectors.